What exactly is torque? Should I care?

The first one is straightforward. The second, however, can get a bit convoluted.

The exact language varies but, in the realm of golf shafts, torque is a number (measurement) that communicates how much a shaft twists under a prescribed amount of force. The lower the torque number, the greater the resistance. And vice versa. For example, a piece of rebar would have very little torque whereas braided rope would produce a much higher number.

TORQUE BASICS

The amount of torque a shaft has doesn’t matter. Or, more accurately, torque isn’t universally applicable. Lower torque isn’t better. And higher torque isn’t bad. It’s not like counting calories.

That aside, the conventional thinking that higher swing speed golfers who produce more force throughout a swing can benefit from shafts with less torque has merit. But it’s not exclusively true.

Just as the inverse—that slower swing speed golfers always require shafts with greater torque—isn’t entirely accurate either.

So what is the correct answer? As you likely expected, it depends.

Most every piece of golf equipment has measurable characteristics: loft, lie, face angle, weight, balance point, etc.

This creates equal parts clarity and confusion. Plenty of characteristics are subject to uniform measurement systems. For example, loft is measured in degrees. Weight is recorded in grams. And pretty much everyone abides by the same system.

But torque is different.

COMPLICATIONS

Somewhere along the line, you might have heard that lower torque shafts are more accurate. Or that they are better at resisting forces during the swing. That type of industry language can lead golfers to conclude that “less is more.” That is: less torque is preferable to more torque. And that simply isn’t true.

Ultimately, the goal should be to properly match the golfer to their ideal specifications.

Further complicating matters, manufacturers don’t use the same protocols for measuring shaft torque. There isn’t a single industry standard that determines which portions of the shaft should be measured and how much force should be applied. Most companies measure torque based on the tip section of the shaft. But without consistent norms, consumers can’t make any meaningful comparisons between brands or even shafts within the same brand. Moreover, terms like “low torque” or “mid torque” are, at best, a generic guide.

As a result, companies can massage results to fit the narrative they want. For example, let’s say the goal is to produce a shaft with 3.5 degrees of torque. To achieve a predetermined outcome, the manufacturer applies the desired amount of force to the selected section of the tip. So torque can be a contrived metric rather than an actual measurement of a potentially meaningful specification. It would be like writing down your 18-hole score on the first tee and then playing the round of golf.

I’m not suggesting every shaft manufacturer is complicit or that every brand misrepresents torque values to deceive golfers. But it does happen. And it helps explain why the universal term might not be worth the weight some golfers assign to it.

APPLICATIONS

Arguably, the most interesting current application of torque in the shaft industry is Fujikura’s work around variable torque.

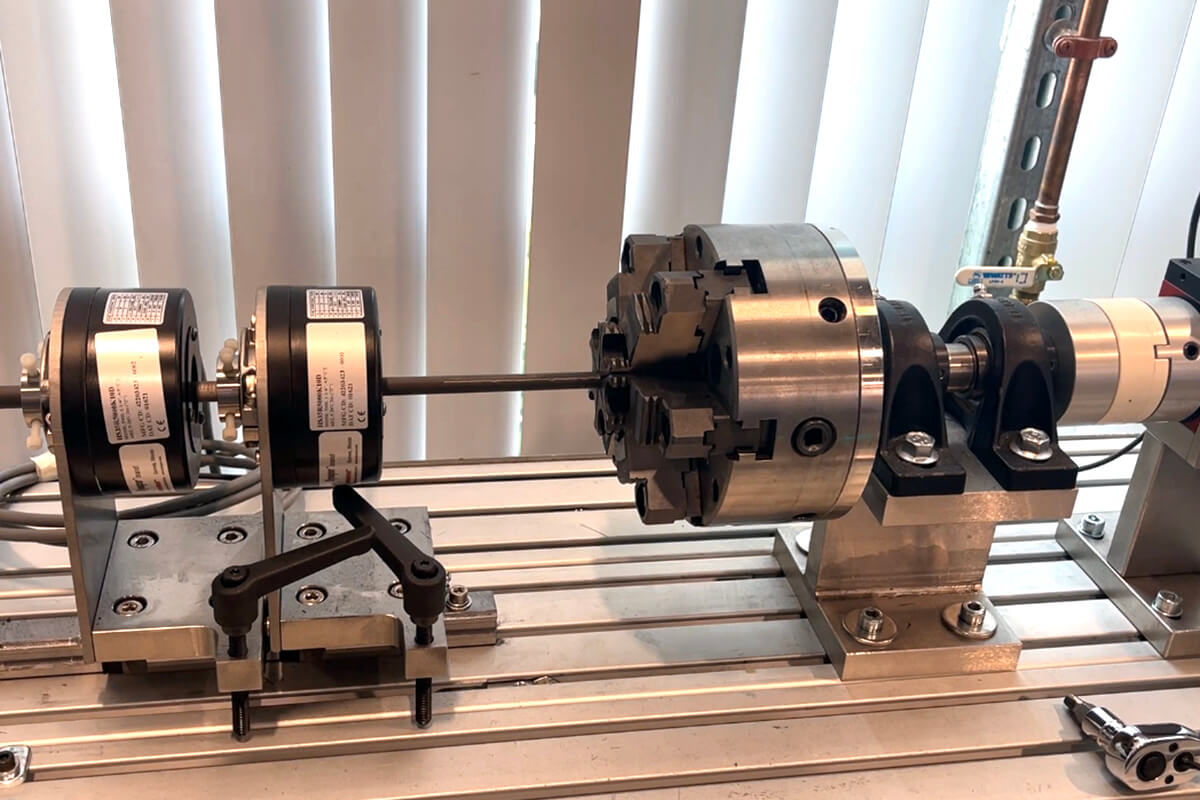

It stands to reason that before you can vary something, you first must measure it. To accomplish this, Fujikura utilizes a proprietary machine that determines two sets of torque values. The first is a composite total torque. Let’s say that number turns out to be 4.2 degrees. The same machine also helps engineers determine how each section of the shaft (butt, mid, tip) contributes to that total number. To clarify, shafts do not have uniform torque. Put differently, the torque measurement in the tip section is not the same as the butt or mid-section.

The application of this line of thinking is that Fujikura can alter the torque profile of each section of the shaft to accomplish specific performance goals. Speeder NX is the first Fujikura shaft to feature Variable Torque Core technology. With Speeder NX, Fujikura focused on stiffening torque in the tip and handle/butt sections. In player testing on Enso, Fujikura’s proprietary 3D-motion capture system, Speeder NX helped golfers better control dynamic loft and face closure rates.

In addition, the recently launched Ventus TR employs a similar, though more isolated, strategy. Specifically, Fujikura utilized a nearly weightless Spread Tow carbon fabric to increase the torsional stiffness in the handle section.

Fujikura isn’t claiming that the thinking is revolutionary. Torque and its role in shaft design aren’t anything new. That said, quantifying torque over the length of the shaft using modern technology is significant. Taking it a step further, Fujikura is applying this information to provide golfers with a more extensive library of shafts to better address the unique swing characteristics of a wider array of players.

If we agree that no two golfers swing the same, it seems reasonable that a greater variety of shaft profiles can only be a good thing. Right?

What questions do you have about torque? Or other shaft topics? Let us know.

Vic

11 months ago

There is a golf shaft testing website.