In an effort to consistently push our understanding of golf physics and develop elite-performing products, PING conducts a wide range of tests utilizing various tools and equipment. One of the most common tests we perform at PING when evaluating the performance of a new prototype or design is a PING Man (robotic) test. A PING Man test allows us to generate very repeatable and specific club head deliveries (rates and orientations) and impact locations. This is fantastic for studying specific elements of a design and understanding their influence on impact dynamics. Robotic testing serves as a great complement to player testing, which gives us insight into how new designs perform in the hands of a player. In many cases, the two tests can produce different results, and analyzing the differences can sometimes lead to the most interesting insights.

PING’s swing robot has an interesting history. The first generation of PING’s swing robot was named Mr. PING and was designed by PING founder Karsten Solheim in the mid-1970’s. He decided to design his own after testing his clubs on other swing robots of the day. He wanted to design a robot that would swing more like a real golfer, which incorporated a free wrist and a shoulder. This design allowed for an upward motion of the lead shoulder at impact and an inertially-controlled swing path that did a great job aligning with the natural swing of a player. Over the years, the PING swing robot was renamed PING Man (around 1980) and has undergone several upgrades. The latest version of the robot — its fifth generation — utilizes a motorized tee that allows for automatic re-teeing of balls and precise positioning of the impact location. We then use launch monitors, high-speed Phantom cameras, and other equipment to measure elements of interest.

A great example showing the benefits of robotic testing can be seen in comparing three different 7-iron designs that have significantly different mass properties. A standard PING Man iron test generates impacts in nine locations on an iron face. From the data at these nine positions spanning +/- 0.5 inches heel-to-toe and +/- 0.25 inches high-to-low, contours can be created that show how parameters like ball speed vary across the face. In the figure below, the ball speed variation across the face of the three 7-irons is compared. It is clear that Club A generates the fastest center ball speeds and maintains those ball speeds over a larger area.

Another interesting element of PING Man tests are the ways we simulate different conditions. For some tests, we hit shots using balls we’ve misted with water, and other times we tape grass in front of the ball to understand how these conditions influence the performance of different designs. It is a bit of a joke around engineering that the taping of grass for PING Man tests is a rite of passage for engineering interns and new hires. We will take grass straight from the range to tape and set-up on the PING Man tee. In particular, testing in these conditions for both partial and full wedge swings plays a big role in the development of PING wedges, most recently our Glide 2.0 line.

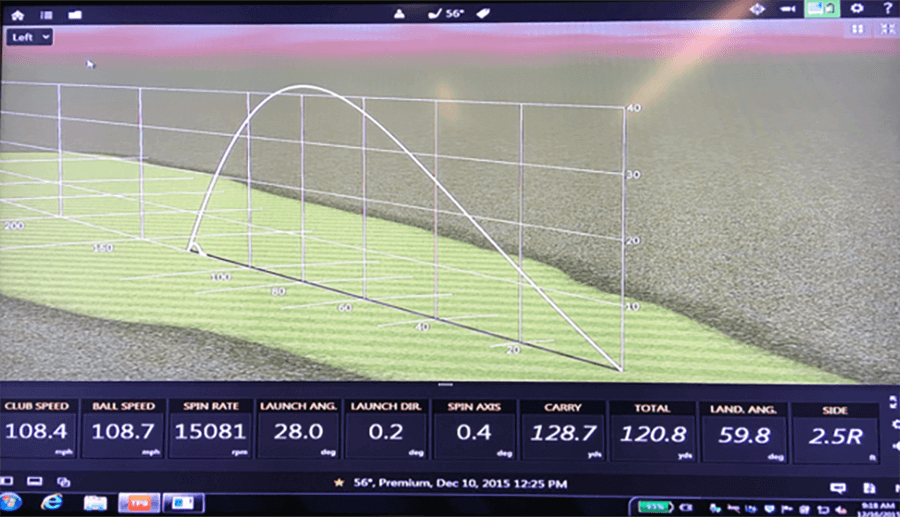

Some days we use PING Man to test conditions that are not necessarily realistic, just to satisfy our sense of curiosity. When we were working on validating a friction model, we decided to have some fun and see what it would take to exceed a 15,000 rpm on a full-swing wedge. We found our answer by cranking up PING Man to swing around 108 mph with a standard 56-degree wedge. That ball was sizzling and sucked back over 20 feet on our Bermuda grass range. I included a picture of the Trackman data from that shot to show what that trajectory looks like.

In conclusion, PING Man is a critical piece of our engineering process at PING. Not only is the PING Man swing robot an iconic piece of test equipment at PING, it is also something we use daily to validate our products and ensure we continue to deliver equipment to our customers that will help them play their best.

mizuno29

7 years ago

Ping will always be around, they make quality products that really perform.