MyGolfSpy recently visited the North American HQ and R&D laboratory of shaft manufacturer Fujikura. The objective was simple: take a peek behind the curtain and get an unvarnished look at how the brand creates a shaft, from ideation to the final, consumer-ready version. It’s difficult to capture everything in a single piece of content, so we didn’t. However, what we did discover is that while the shaft industry has plenty of smoke and mirrors, clear differences exist between brands.

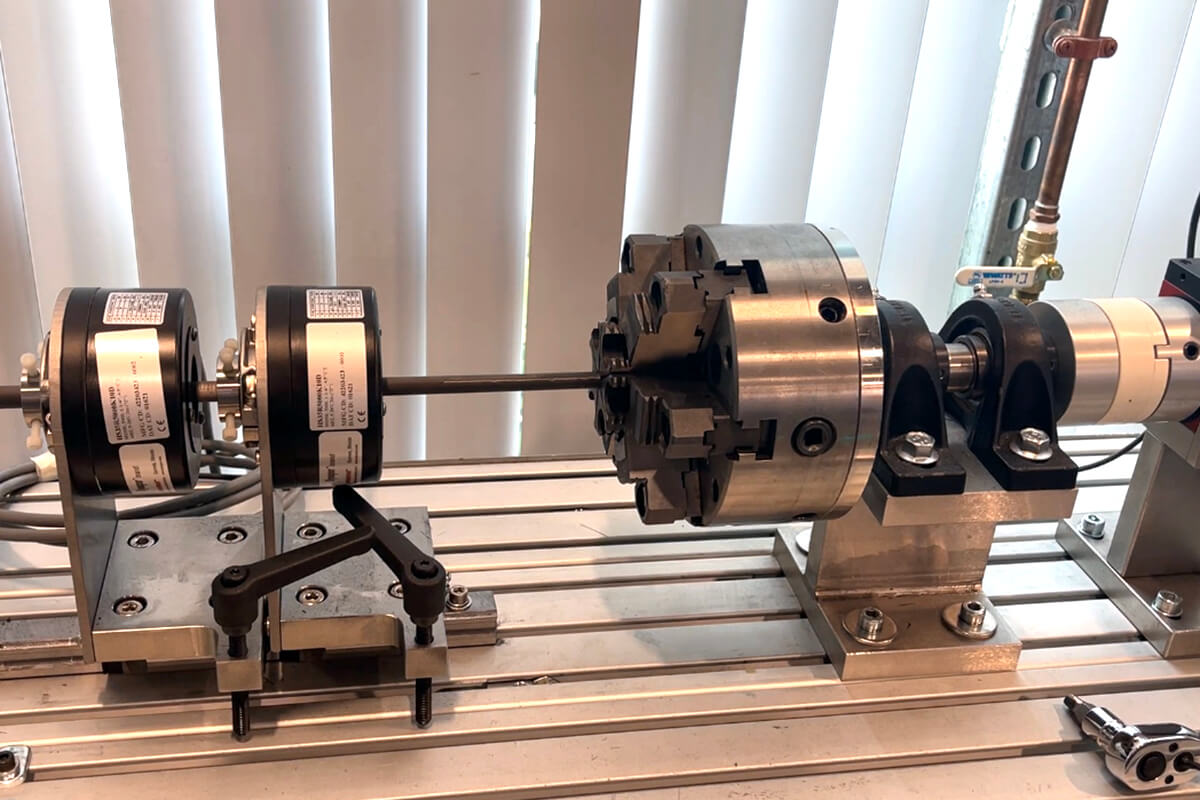

For Fujikura, a good bit of that distinction starts with ENSO, its proprietary 3D motion capture system. We’ll take a deeper dive into ENSO in a separate article. In addition, keep an eye on social media for our video segments featuring Fujikura’s “Torture Rack” and the various steps in the shaft production process.

Then, there are always tidbits of useful information that come up in casual conversation which merit some additional attention.

With that, here is a collection of 10 such items to keep in mind when buying or getting fitted for a new shaft.

1. GETTING FITTED

Getting fitted into the correct shaft requires that you understand the role each component plays in the process. That is, as much as you might focus on the shaft in a shaft fitting (which makes sense), the shaft is one component of a larger system.

What this means is that the best shaft for you is a function of the mass properties of the head as well as the weight, length, face angle, etc. If you change any of these variables, it can impact how well that shaft will perform.

2. SWING SPEED

Swing speed is an integral data point in any shaft fitting. But be careful with any fitting catch-all guidelines such as “slower swingers need softer shafts and faster swingers need stiffer shafts.”

Certain commonly held fitting beliefs exist because there is some measure of truth in them. However, that doesn’t mean they should be treated as universal facts.

Tempo, speed, athleticism and physical traits are all unique to each golfer. Case in point: Two golfers, both of whom swing a driver at 100 mph. One has a quick tempo, shorter swing and casts the club very early in the downswing, effectively dragging the club through impact. The other has a longer swing, smoother transition and late release. I’d bet a fancy steak dinner that a single shaft isn’t optimal for both golfers. In fact, it’s nearly as certain as the sun rising in the east.

3. STOCK SHAFTS

You don’t have a $400 shaft in a driver that you just bought for $449. The math doesn’t work that way. It’s one of the reasons Matrix Shafts is no longer in business. That said, the stock shaft might look almost exactly like the more expensive aftermarket version but the two are not the same.

In fact, if the shaft in your driver wasn’t subject to an upcharge, one of two possible scenarios is likely in play. The first, and most common, is that the shaft manufacturer won the bid to produce a metric shit ton of shafts for the club manufacturer. And. generally speaking, “winning” means an ability to work within narrow price constraints. The second possibility is a volume-based arrangement where the shaft manufacturer agrees to a reduced cost (less than wholesale) on a shaft made from higher-quality materials in exchange for some level of exclusivity in the club manufacturer’s shaft lineup.

With that, “stock” shafts are NOT inherently bad. It simply means they were designed as a “one size fits most” solution that worked within the price requirements of the OEM. This isn’t to throw shade at any specific shaft manufacturers as they’ve all dabbled in the dubious duplicity of passing off stock shafts as something far more similar to the expensive aftermarket counterpart than is objectively true.

4. TO “PURE” or NOT TO “PURE”?

The topic here is a divisive one. SST PURE is a proprietary process that “identifies the most stable bending plane” of each shaft to optimize performance. But, for an additional $40+/shaft, is it worth it?

That answer is much less clear.

SST Pure proponents will tell you internal studies show clear results of improved consistency and distance. That said, they likely won’t disclose the exceptionally friendly profit margins of what amounts to a rather minimal “per use” licensing fee.

Conversely, I get that it’s uncomfortable for a shaft manufacturer to tell customers that even though they just dropped $400 on a shaft, that to really optimize performance, they should invest an additional $40. That’s a tough sell if you want golfers to also believe your manufacturing technologies are industry-leading.

I can’t speak for all shaft companies. However, Fujikura doesn’t believe that SST Pure improves the performance of its shafts. Anecdotally, one industry insider confirmed that when he runs Fujikura shafts through the SST Pure machine, the sticker ends up in pretty much the exact same place. Does this hold true for steel shafts? Graphite shafts from other companies? Now, that’s a rabbit hole inside Pandora’s Box.

5. SO-CALLED “HAND-CRAFTED” SHAFTS

Any language alluding to bespoke, bench-made, hand-crafted, artisan-style products lends itself to a marketing approach rooted in authenticity. Simply, merchandise made by hand is in some fashion better than whatever a machine can do. At least, that’s what some companies would like you to believe.

The reality is that nearly every high-end shaft is hand-rolled. More correctly, the manufacturing process is always a combination of human and machine labor. So, beyond some fancy graphics, is it fair for golfers to question what real value is in any such limited edition or tailor-made shaft?

6. GRAPHITE VERSUS STEEL IRON SHAFTS

Steel is isometric. Carbon composites aren’t. To clarify, steel can be more or less “one thing.” That said, steel shafts have noticeably advanced in the last several decades, particularly uber lightweight steel shafts. However, graphite allows for larger variations in flex, torque and performance throughout a single shaft. Think of it this way: steel is an ice cream shop with three flavors. Graphite is Baskin Robins. One isn’t inherently better but it does offer more options.

7. ONE-WAY STREET?

We often focus on the design intentions of a shaft (EI profile). Basically, this determines how stiff (or soft) each section of the shaft is. And, based on these differences, we believe shaft performance follows logical cause-effect thinking. If a shaft is constructed to be low-launch/low-spin, then it will be low-launch, low-spin for all golfers.

But every golfer is unique. Therefore, every swing is different. Because of this, the shaft can impact the mechanics of a golfer’s swing. The challenge is quantifying all the variables in a way that produces actionable information.

ENSO, a 3-D motion capture system, gathers this type of information. There are three ENSO systems in the world. Shaft company Fujikura has two and PING owns one.

With this information, shaft engineers can examine and isolate the role of shaft specifications in individual swing characteristics. Basically, a shaft can alter the golfer’s path, angle of attack, tempo, etc., of the swing.

Therefore, a golf shaft, like the mass properties of club heads, can induce different launch conditions and shot shapes.

So, can a shaft be draw-biased? Yep. Help alter angle-of-attack? You betcha.

8. SHAFT FAILURE

Shafts break. It happens. However, failure is exceedingly uncommon in the mid and grip regions. If a graphite shaft breaks during the course of normal play, it’s almost always in the tip section. This is the thinnest portion of the shaft, which is also subject to the most force during the swing.

So, if you have a defective shaft that didn’t survive your latest tomahawk flip or Bo Jackson impersonation circa 1989 and the manufacture was kind enough to replace it, they did you a solid. Maybe send them a “thank you” card.

9. IS TORQUE MISLEADING?

By strict definition, the torque of a golf shaft is how much the shaft twists when subjected to a certain amount of force, measured in degrees. In simple terms, torque is a shaft’s resistance to twisting.

However, the measurements can be misleading. The standard industry practice is to measure the torque by applying force only to the tip section of the shaft. But what about the rest of the shaft?

Low torque is often a characteristic of expensive (exotic) shafts. I won’t get into all the specifics of tensile strength, pitch versus pan fibers and bias layers. But plenty of shaft manufacturers use premium materials in the tip section to produce desirable torque ratings and cheaper materials in the mid/butt sections.

It’s something like only studying the answers to questions you know will be on the test.

10. THE RECIPE AND CHEF MATTER.

Golf shafts aren’t that different from golf balls. Consumers generally focus on a single result—performance. To a degree, that makes sense. But, like golf balls, the final product is a function of myriad factors—design, materials, R&D, quality control and manufacturing processes.

For each step or element that is outsourced, the company loses a bit of control. Many shaft manufacturers source raw materials from several major vendors. That’s to be expected.

But before you invest several hundred dollars in a shaft, it’s worth knowing who the chef is and where they got the recipe. Unfortunately, it’s easy to toss some killer graphics on a generic shaft with middle-of-the-mall materials and the consumer is none the wiser.

What questions do you have? Where can we dig deeper? What else would you like to know?

David

3 years ago

While I realize all of the data supports fitting, my personal experiences with shaft fitting have been less than stellar. Finding the right fitter has been a challenge. The local club fitters in my area are disappointing because of their high pressure sales techniques, which I have experienced, and my swing is really terrible indoors – clearly psychological. Outdoors, no problem. Since I do not belong to a private club, I don’t have access to outdoor fitting. So, while I believe that fitting is important, and likely beneficial, it really is a process reserved for those with access and money to spend on expensive golf products and services. It’s not necessarily the fault of the industry, it’s just an inherent limitation.